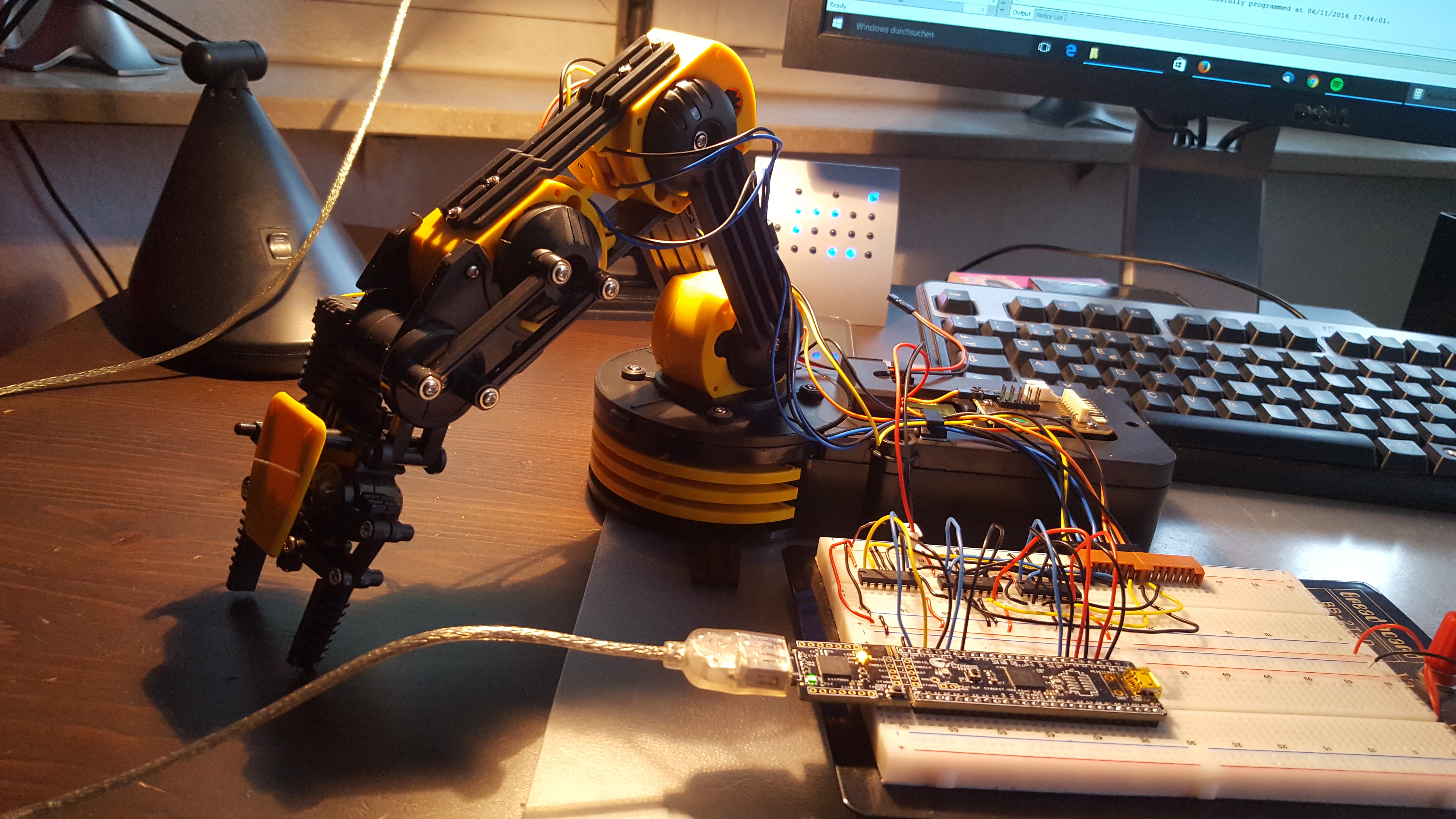

Robot Arm KRS10

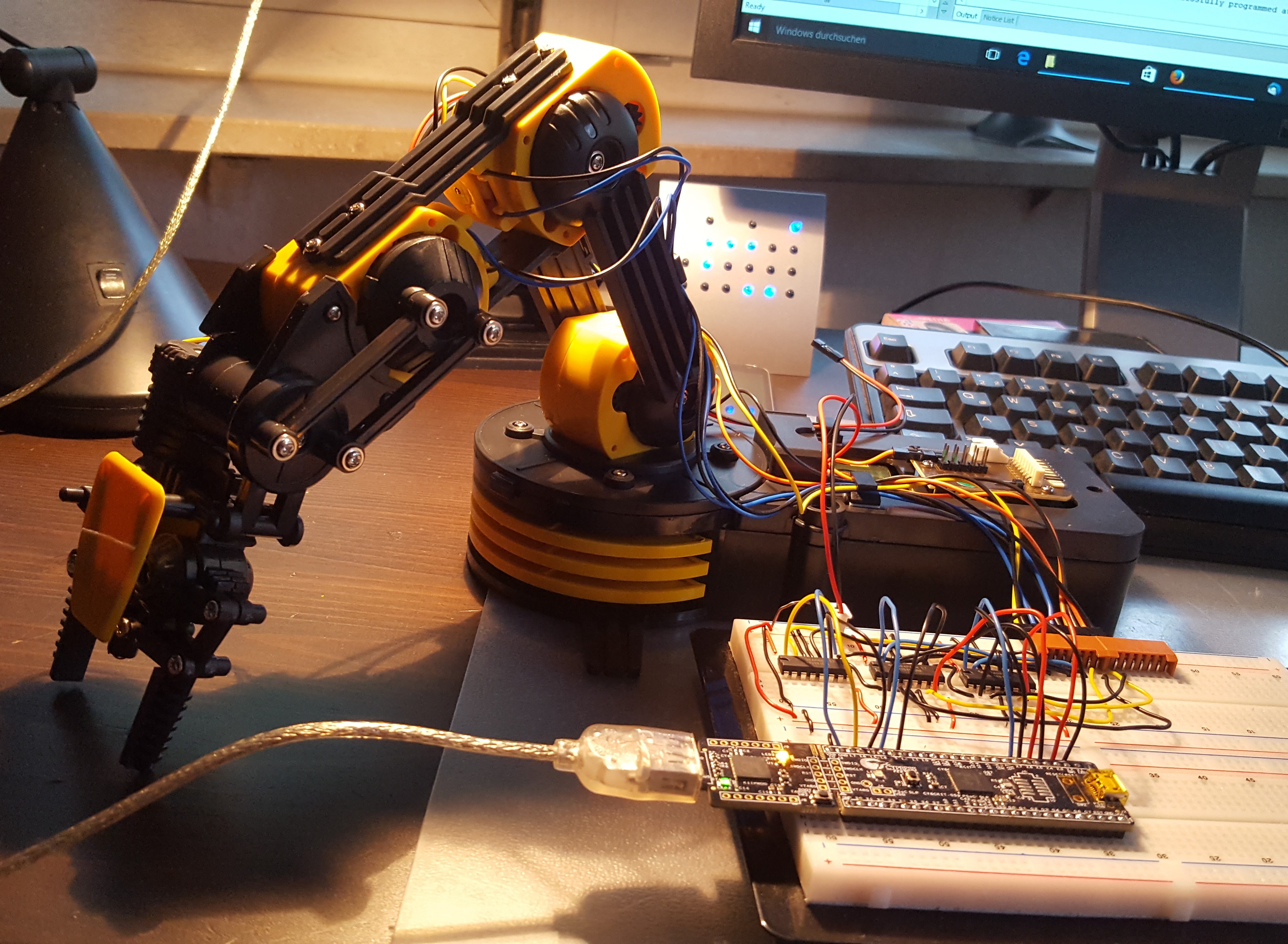

A learning journey from a kids toy to a mechatronic device.

Features

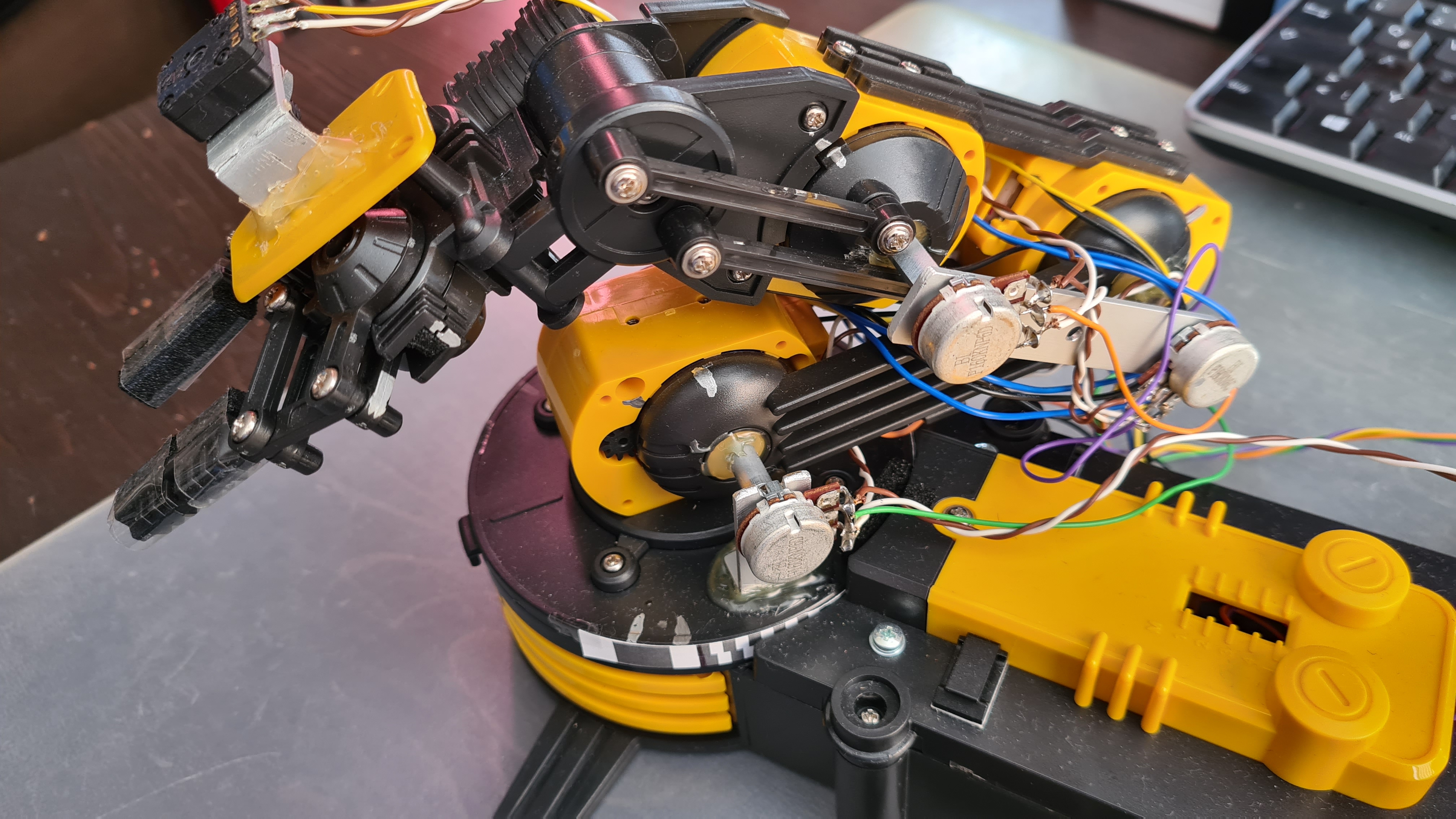

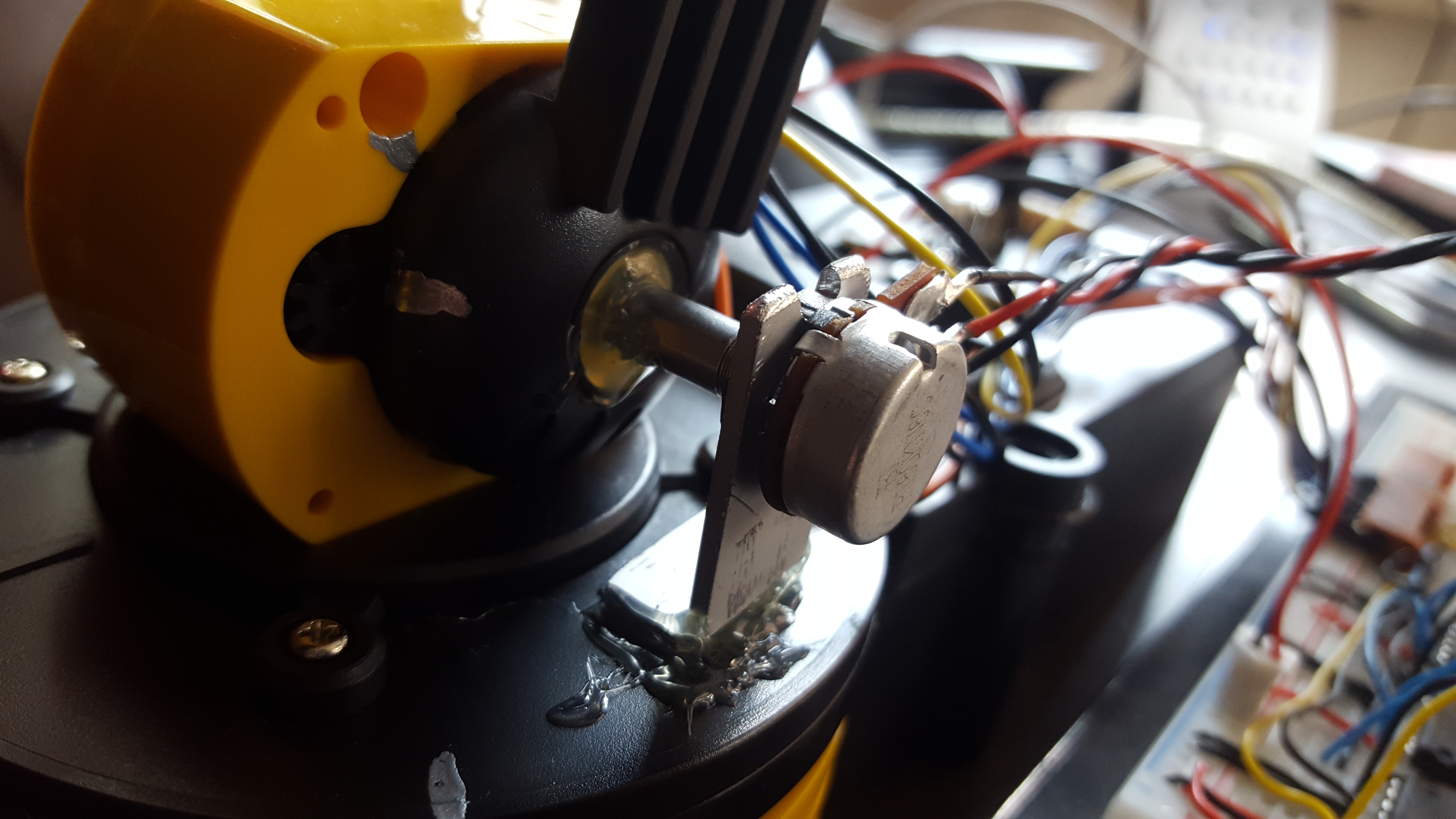

- Position-control of all joints via potentiometers

- Position-control base plate via optical position sensing

- Force-control of grabber via current measurement

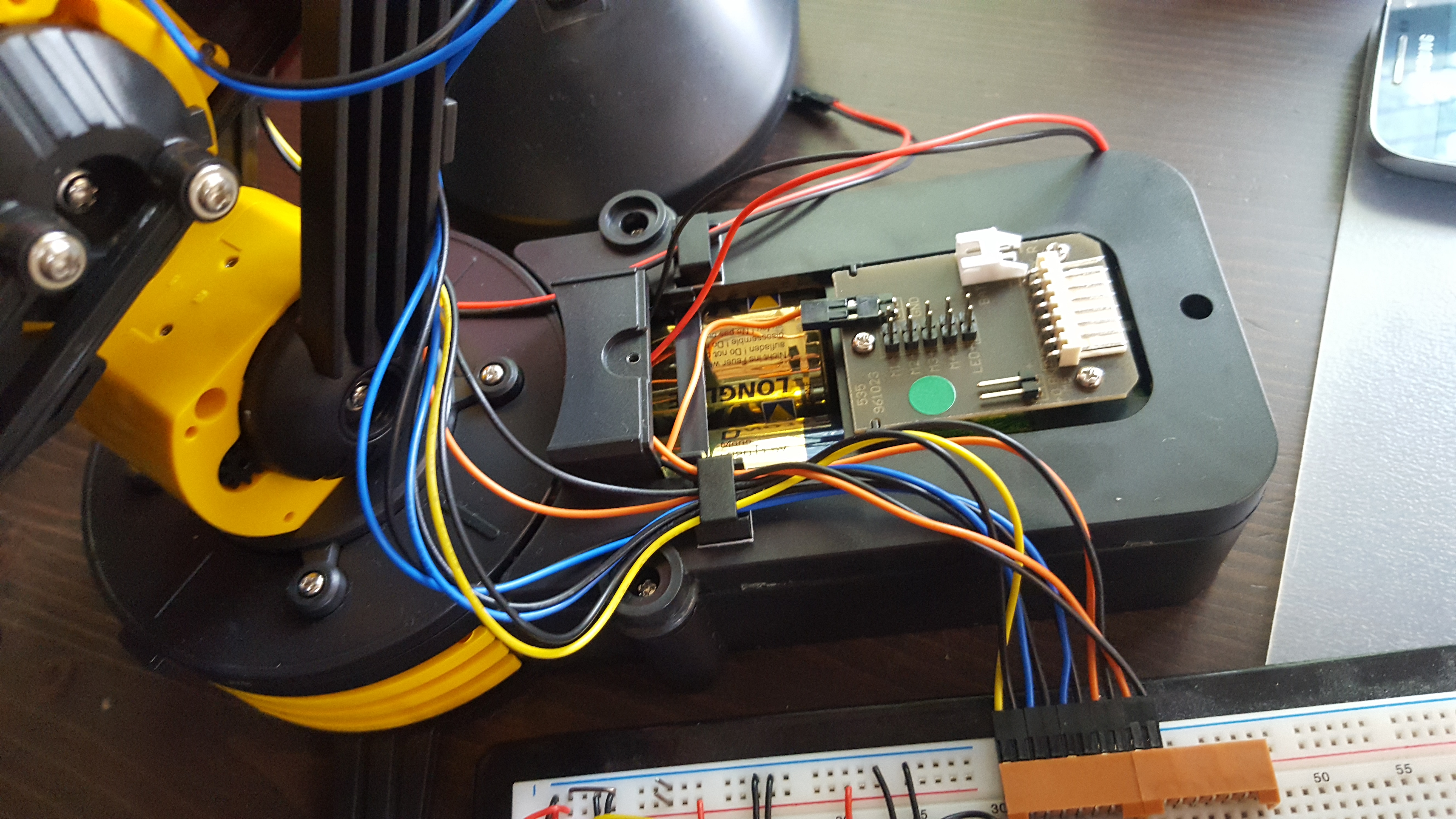

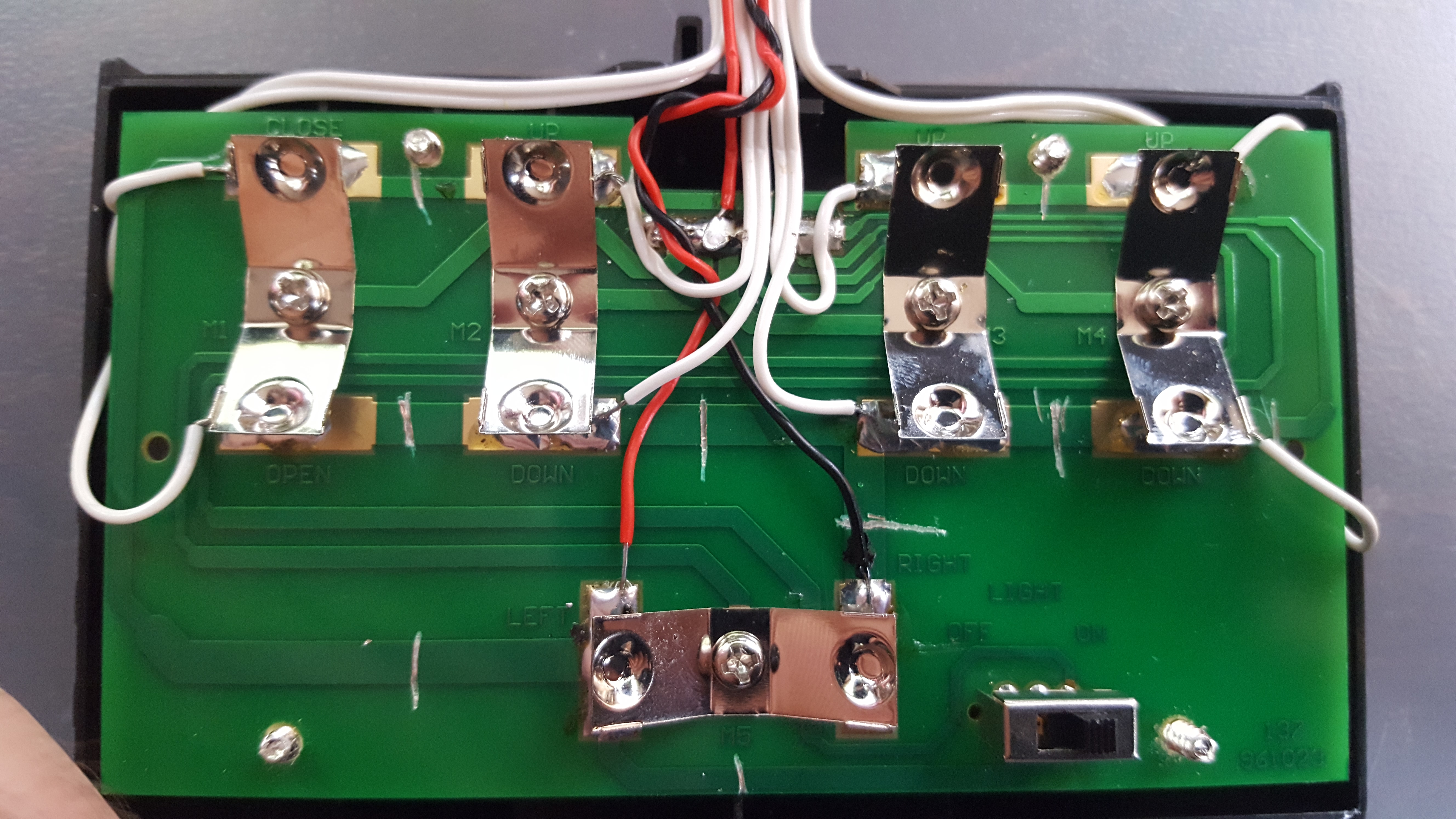

- Manual control via adapted stock remote

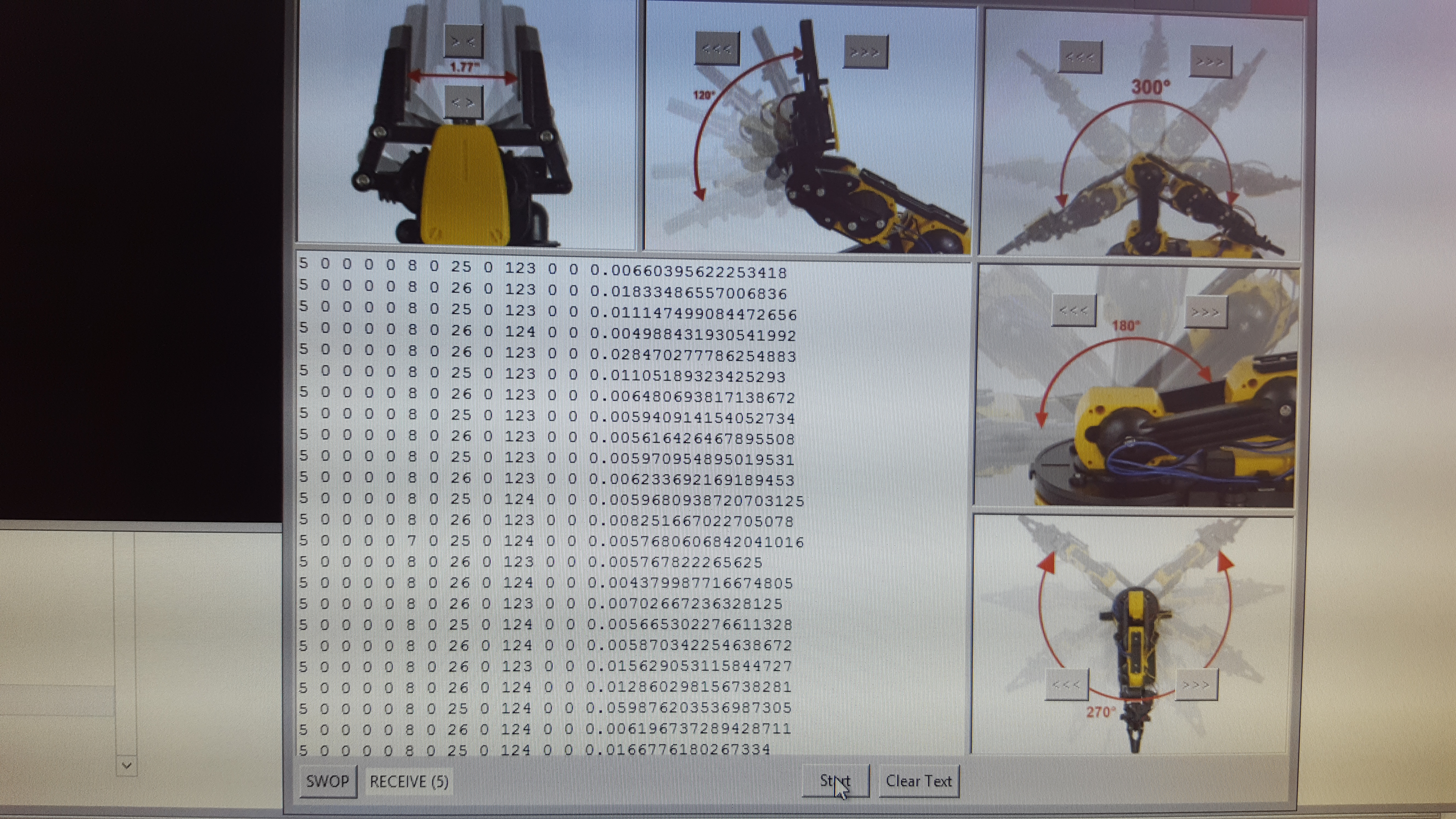

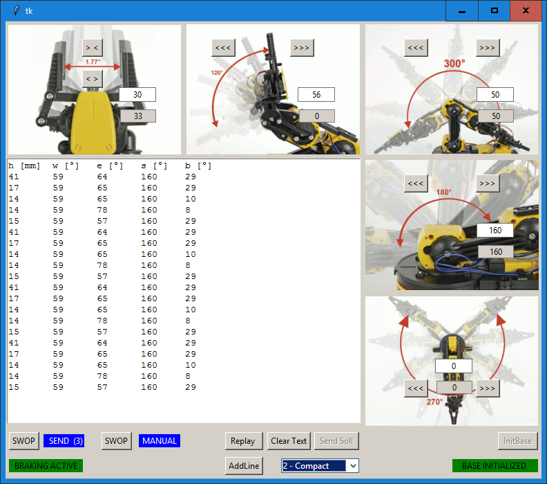

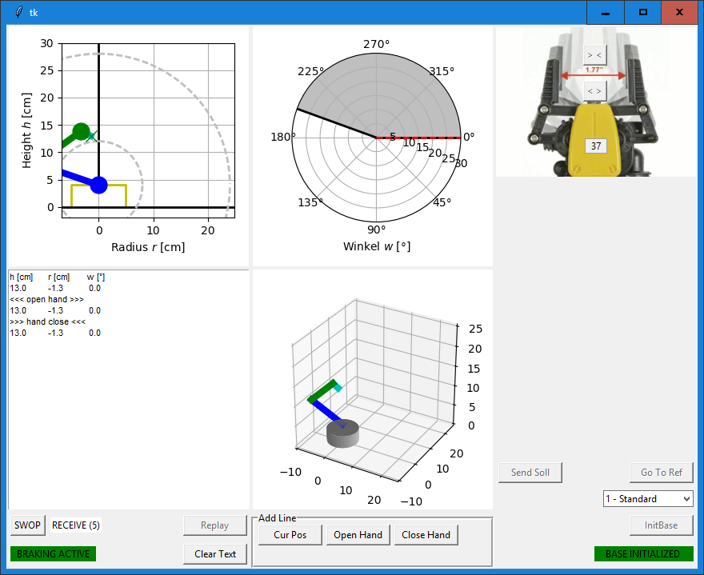

- Usb-based control interface allowing to navigate points in real world coordinate system

- Recording, storing and replay of moving profiles

Main Components

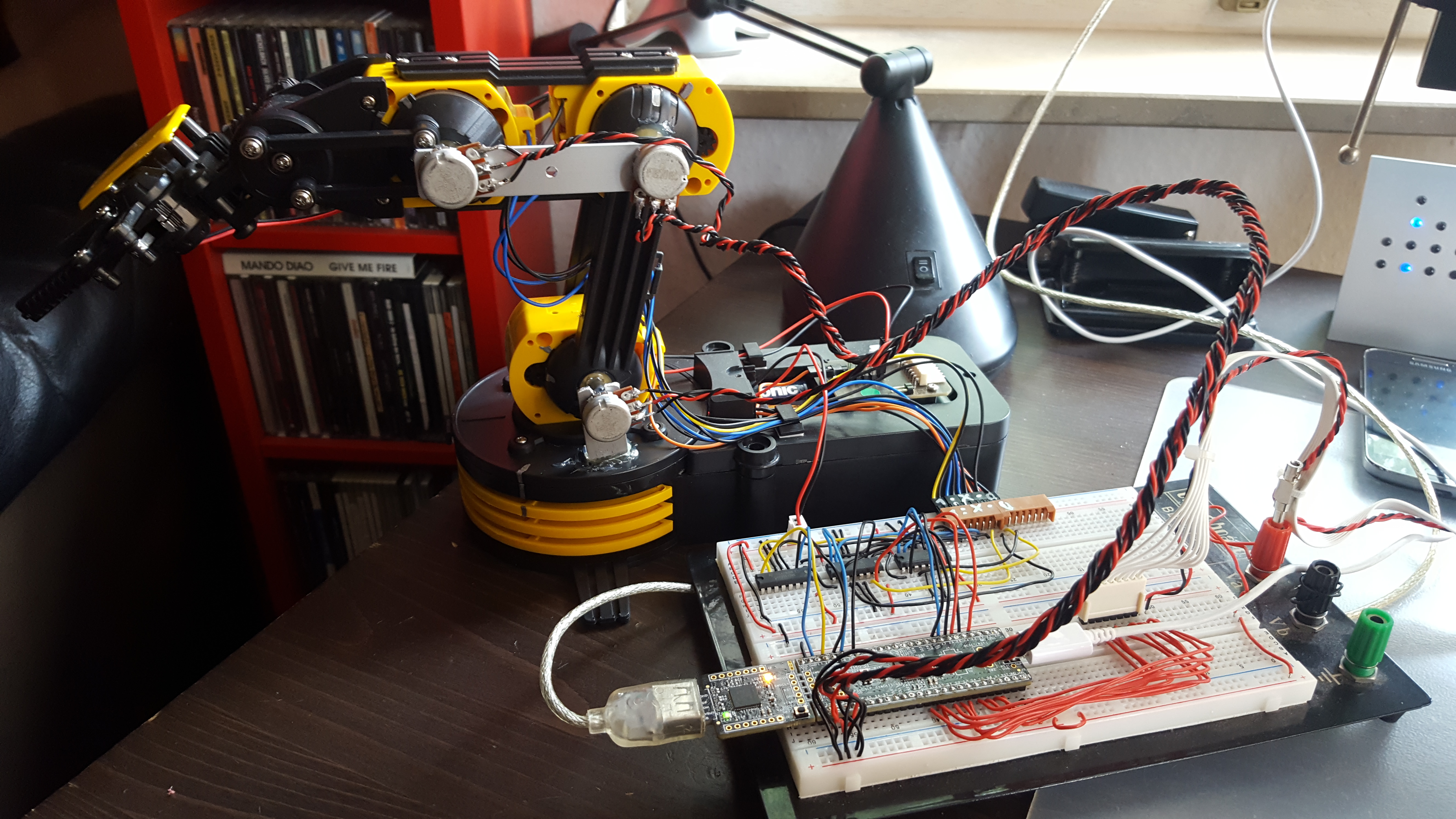

- 1x KRS10 robot arm

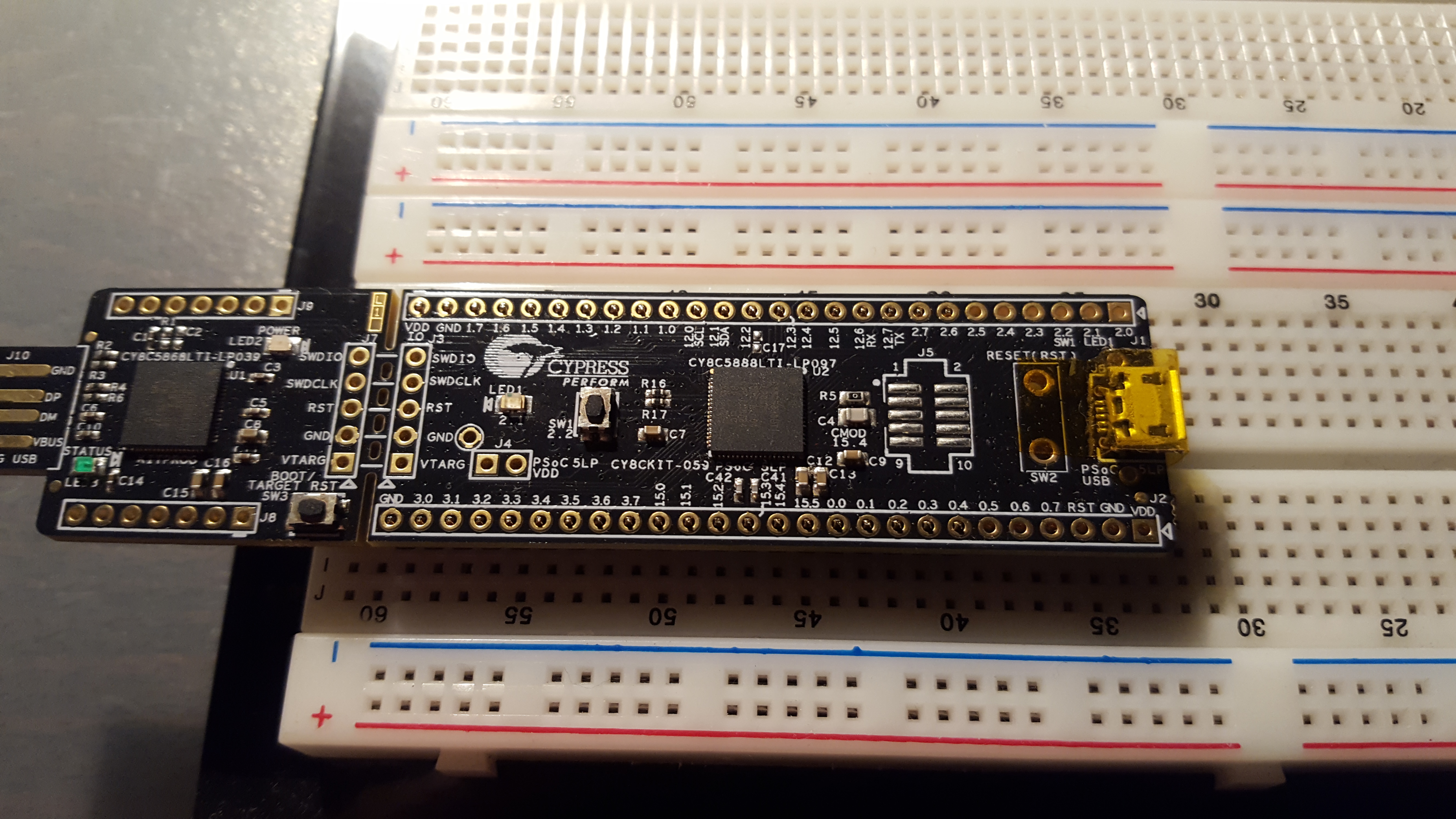

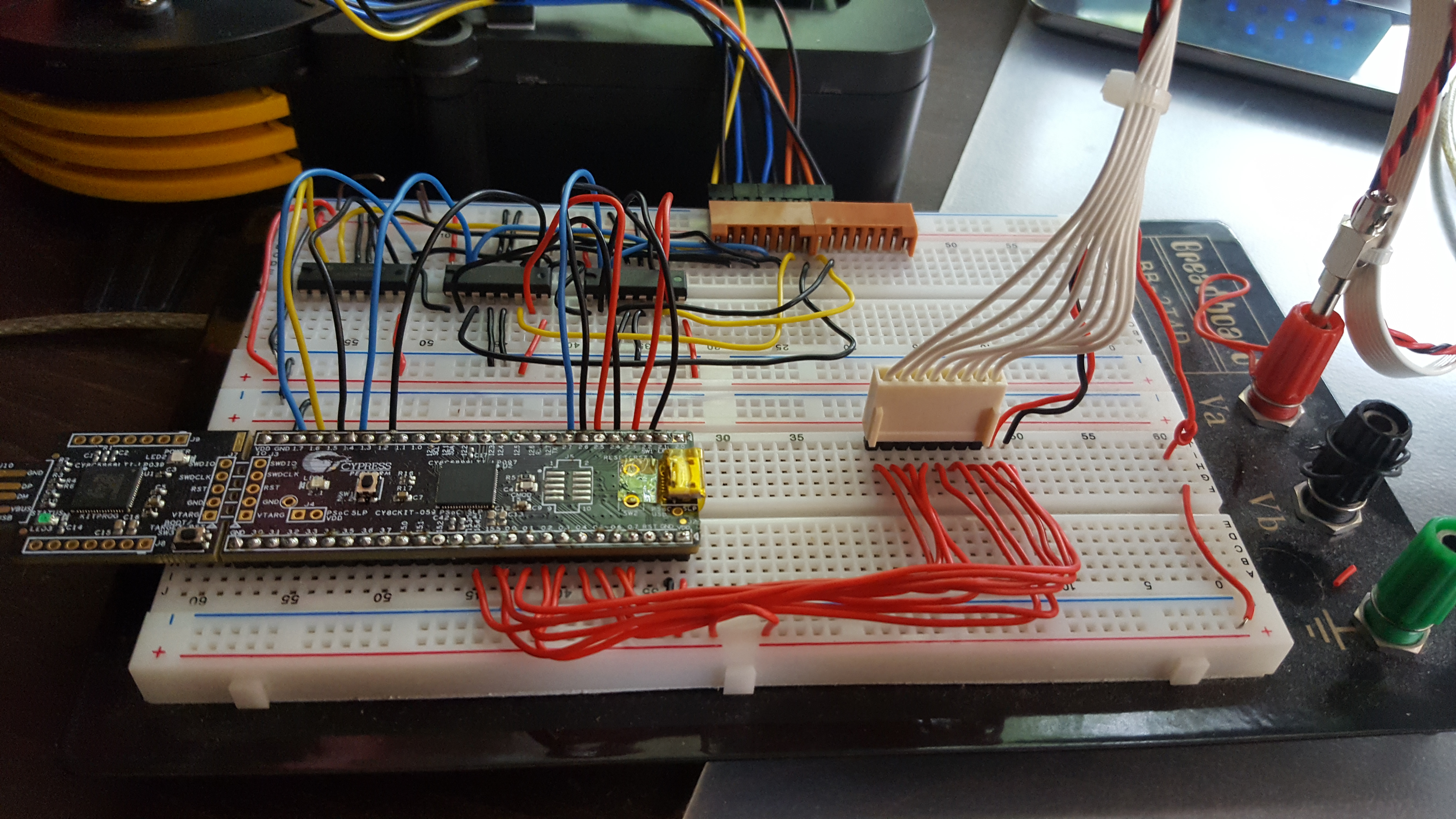

- 1x CY8CKIT-059 PSoC 5LP developement board

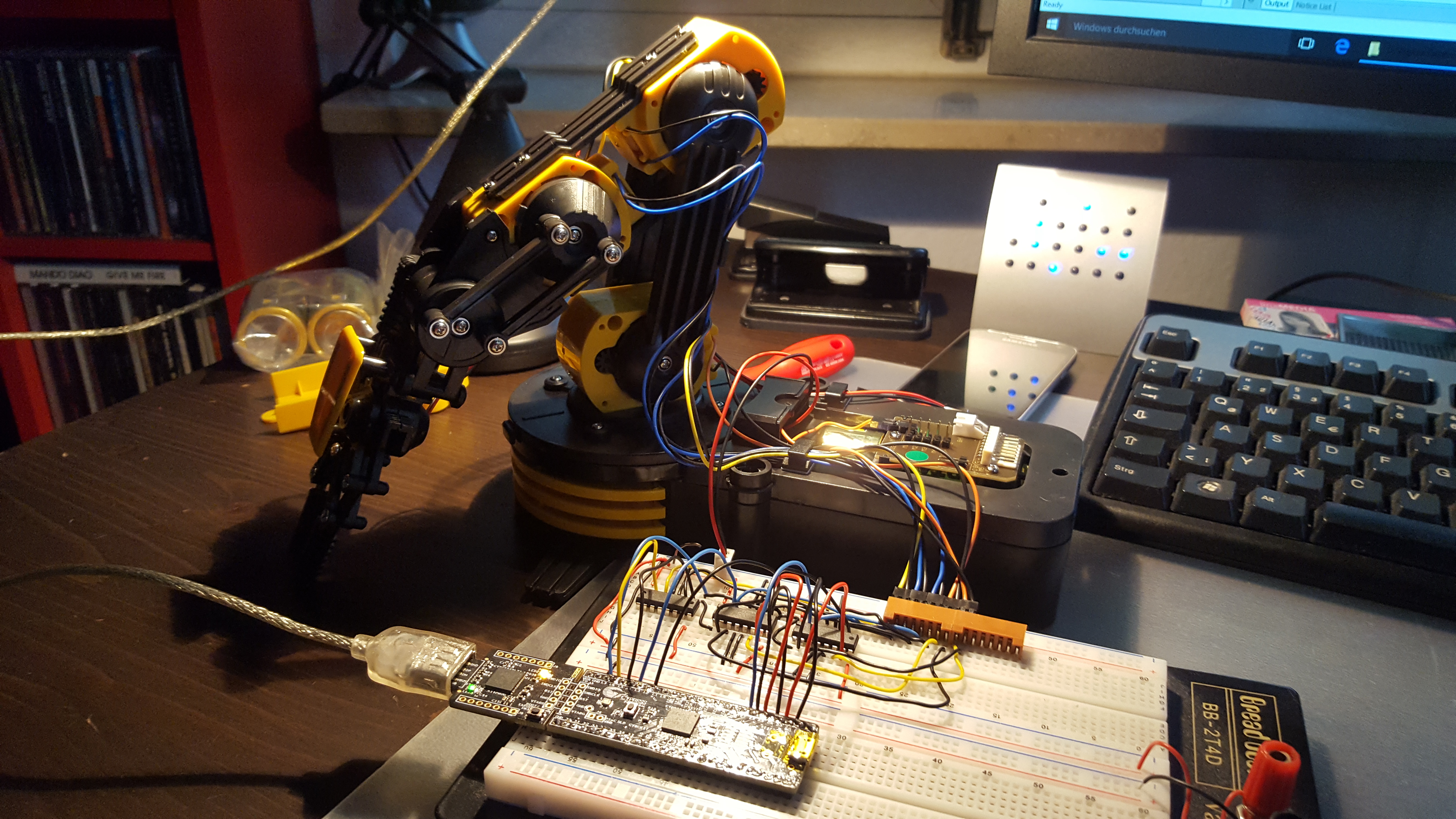

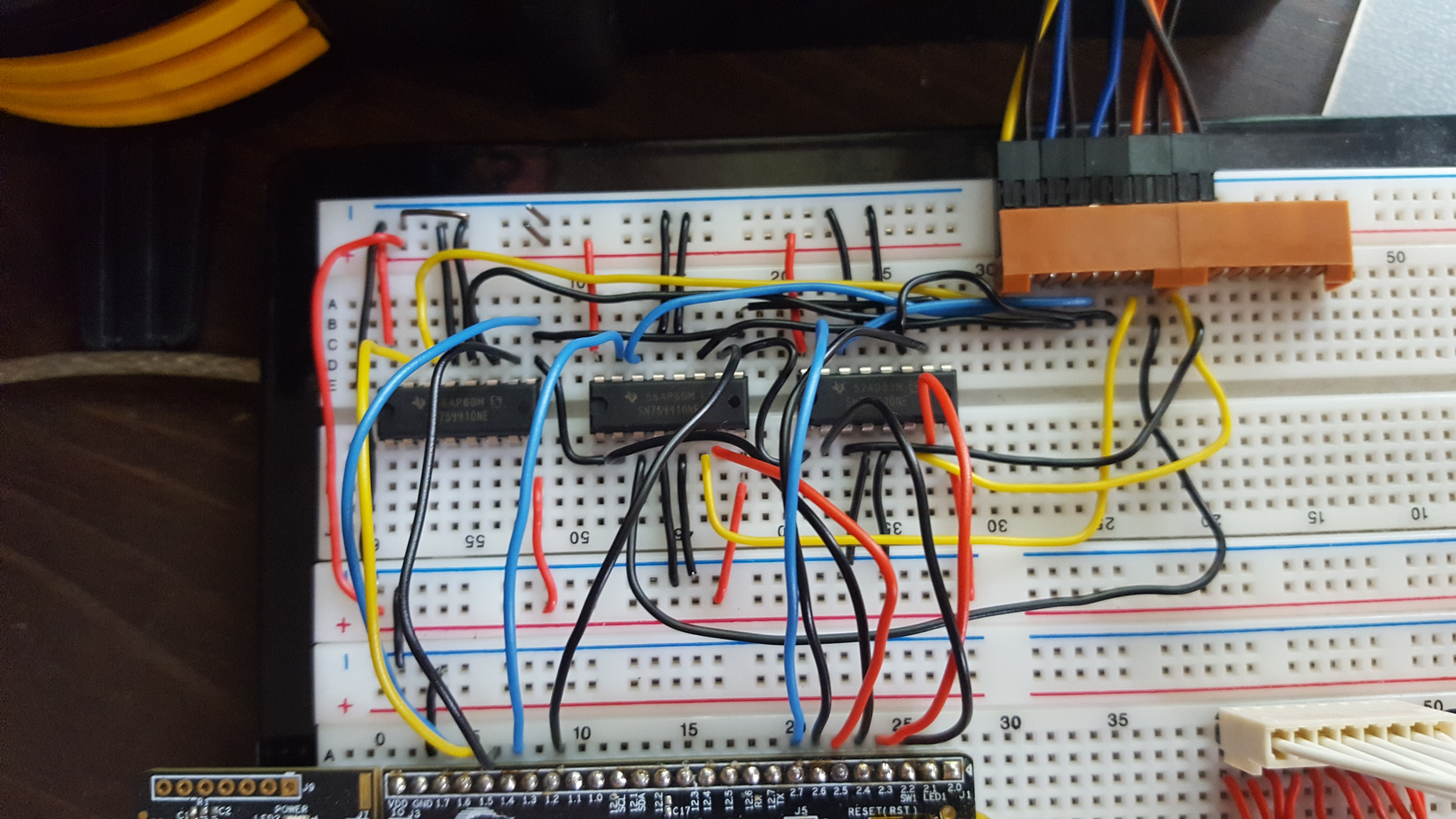

- 3x SN754410 Quadruple Half-H Driver

- 2x ITR9904 Opto Interrupter

- 1x SN74HC14 Schmitt-Trigger

Programming languages

- Python

- C

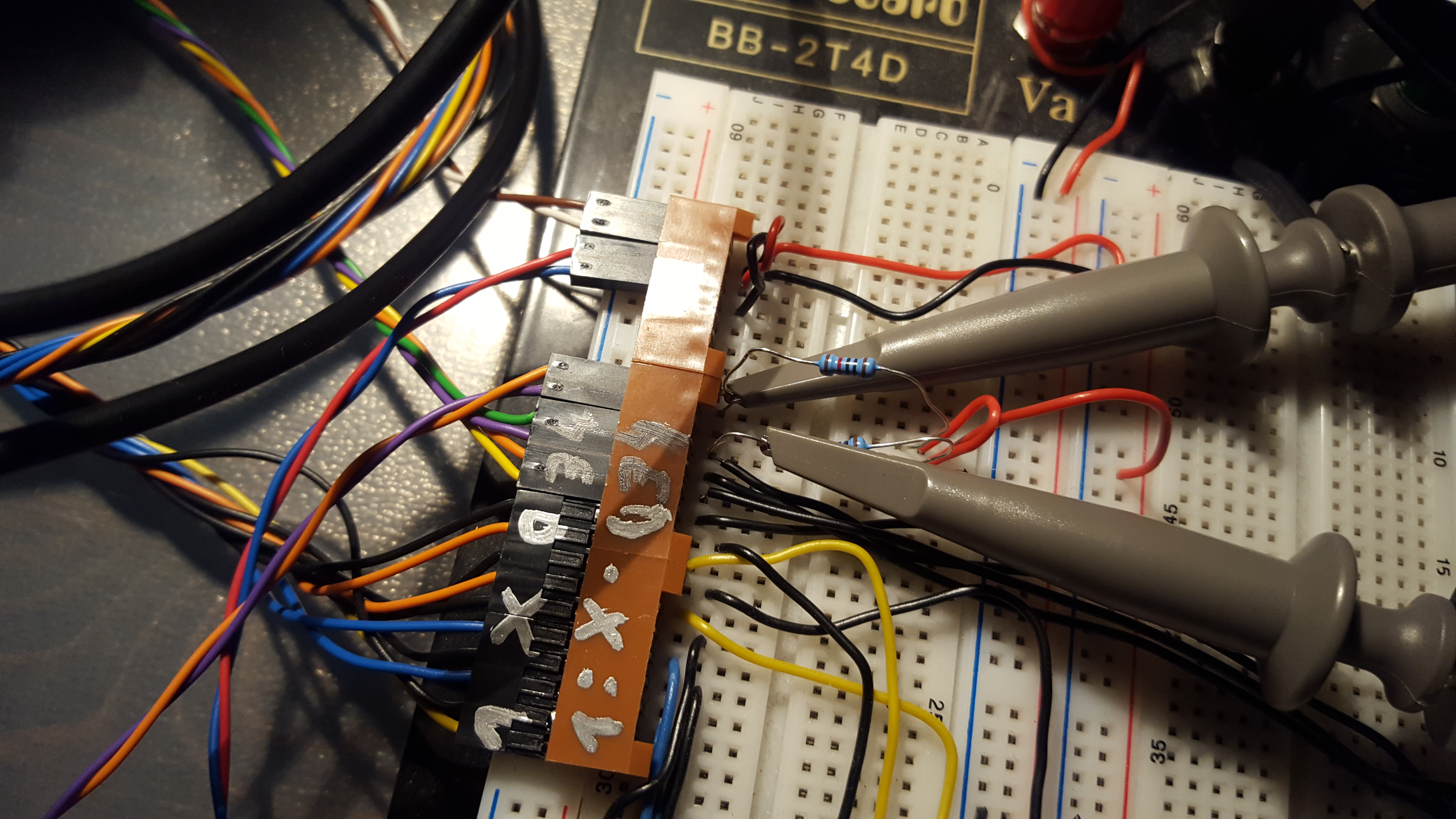

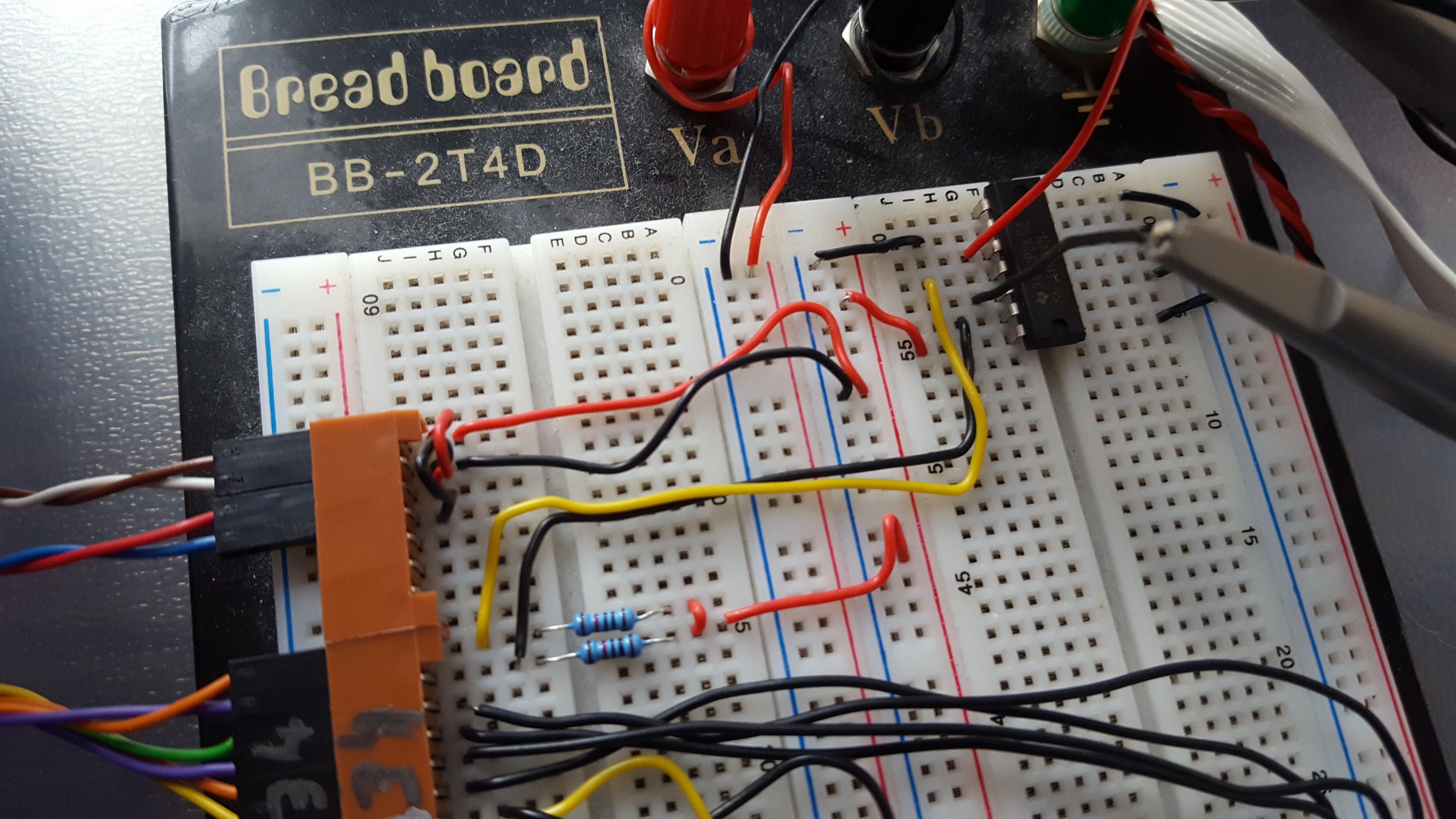

The Blockdiagram is an essential tool while building the prototype on a bread board or via direct pinning in an early project phase.

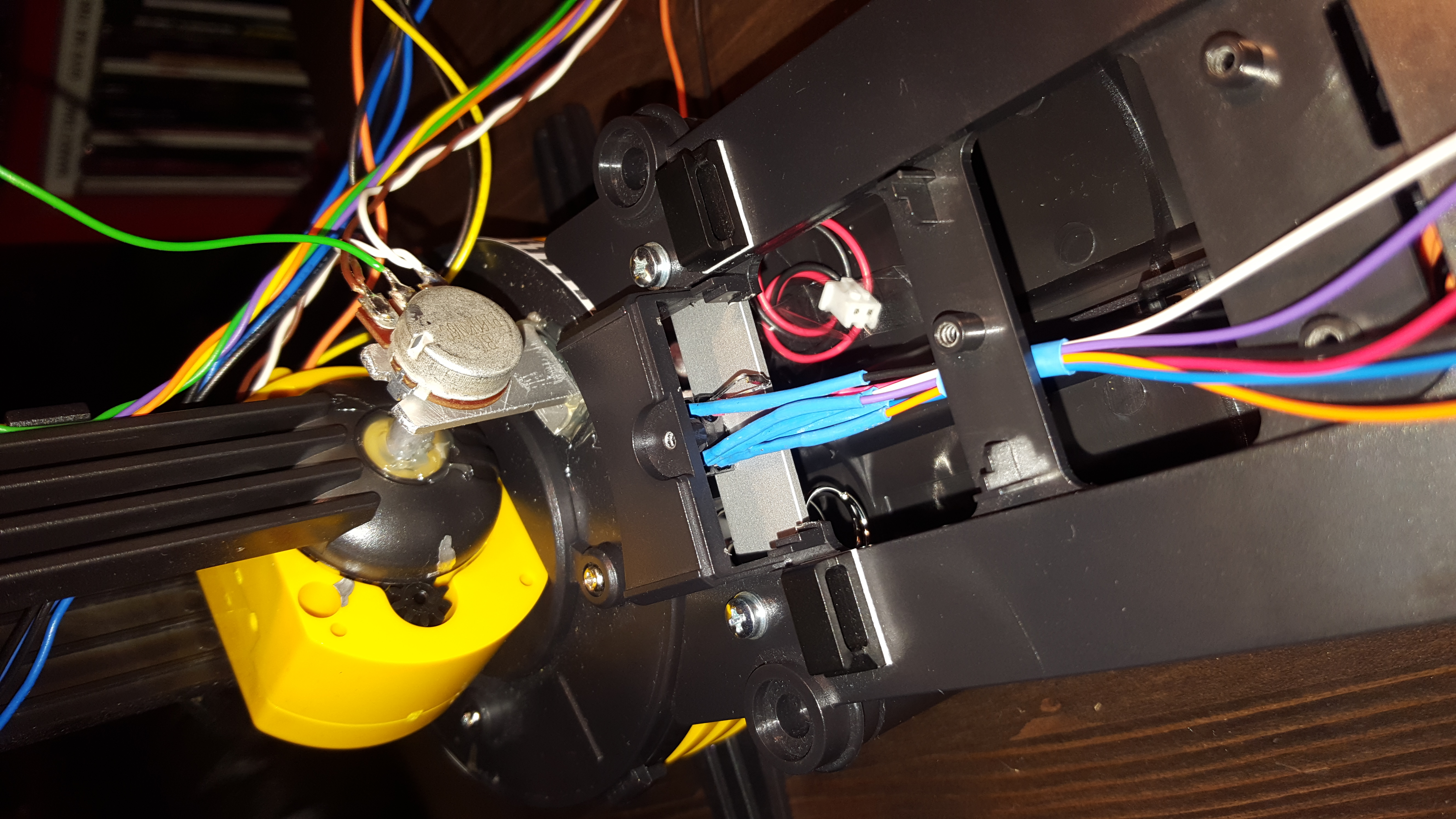

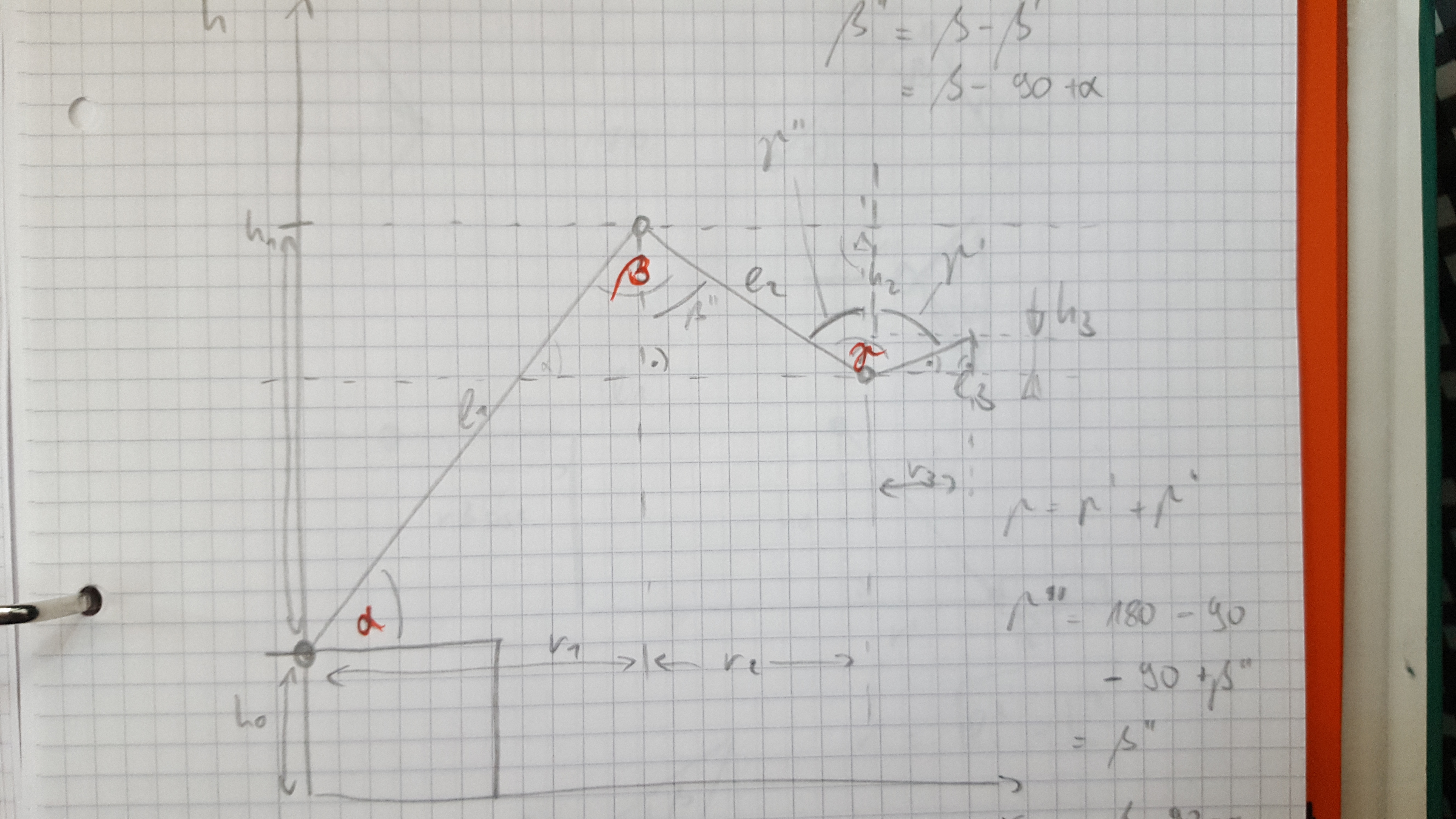

All joints and the claw mechanism are equipped with potentiometers to measure the actual position. The stock DC motors are driven via the Half-H Bridge Drivers. The stock remote control is rewired and read into the microcontroller to retain a manual operation mode.

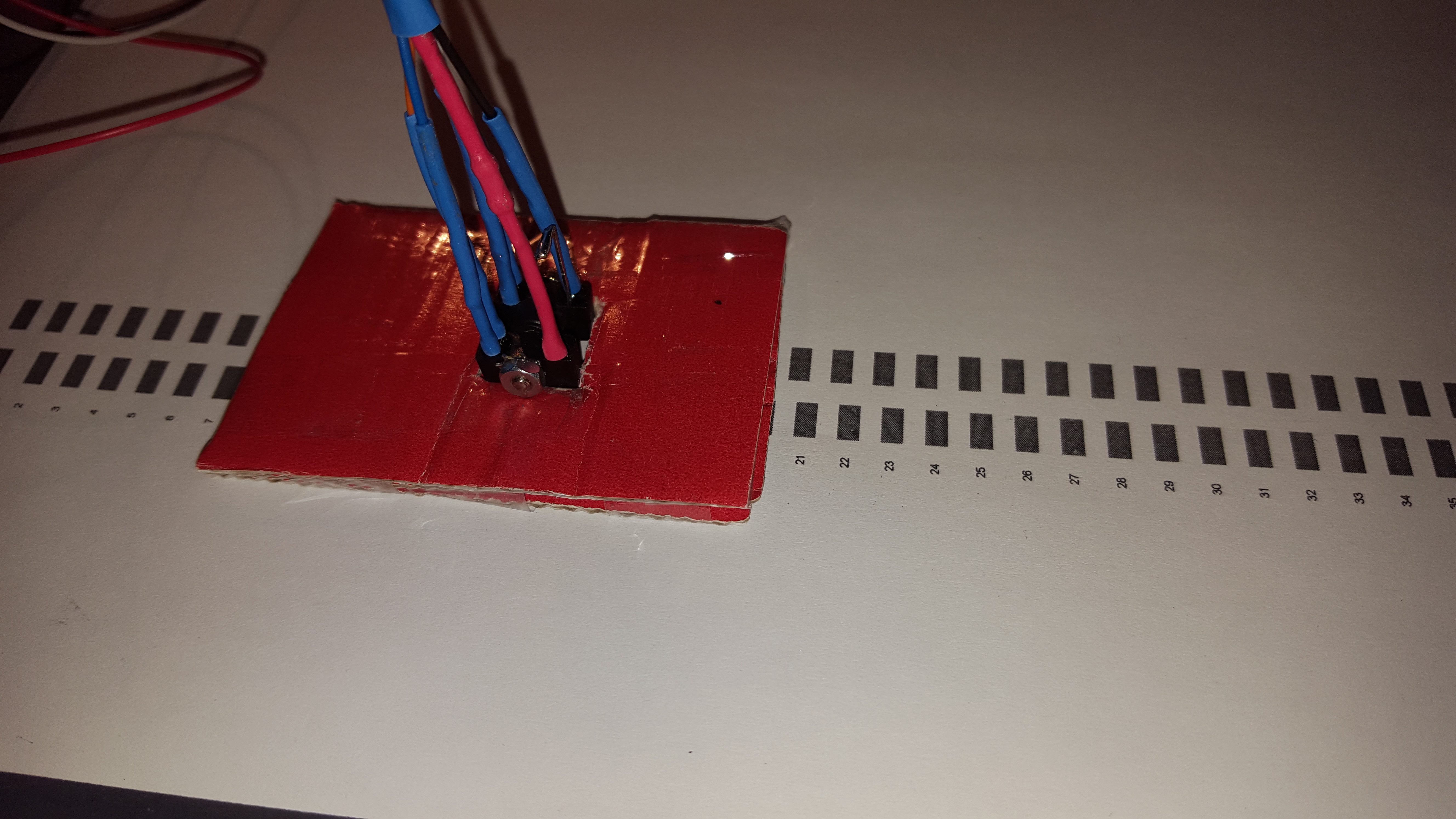

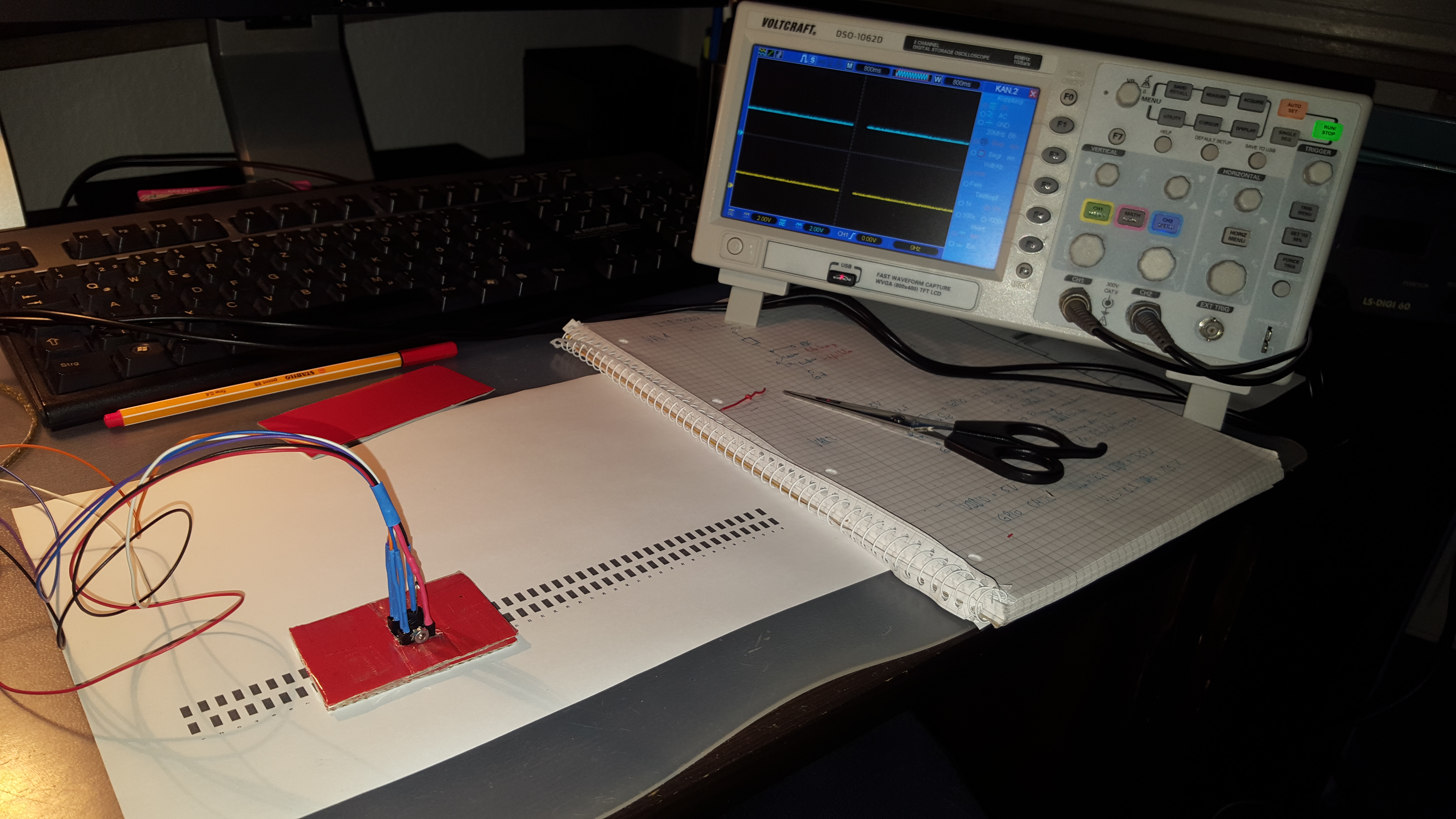

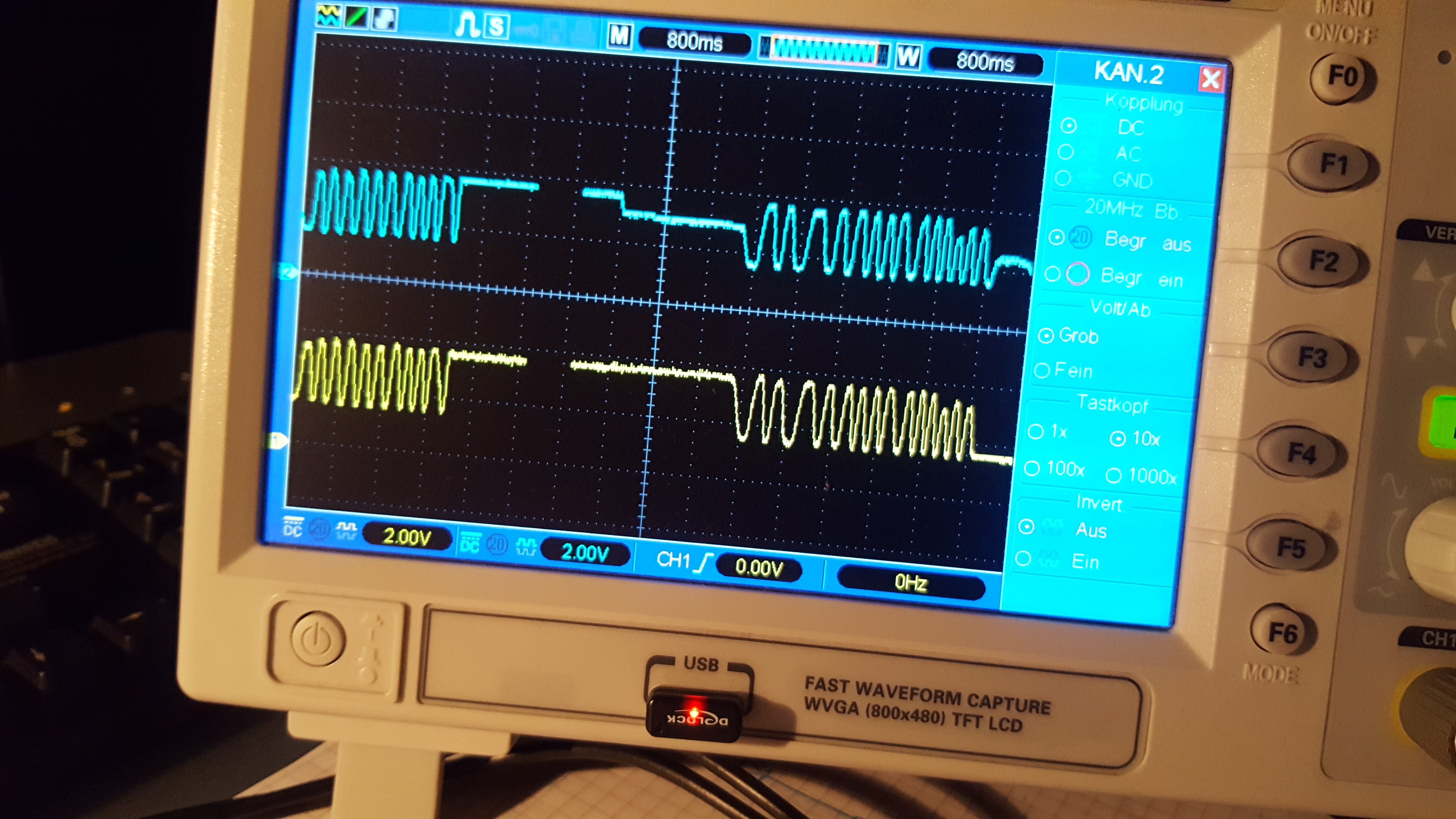

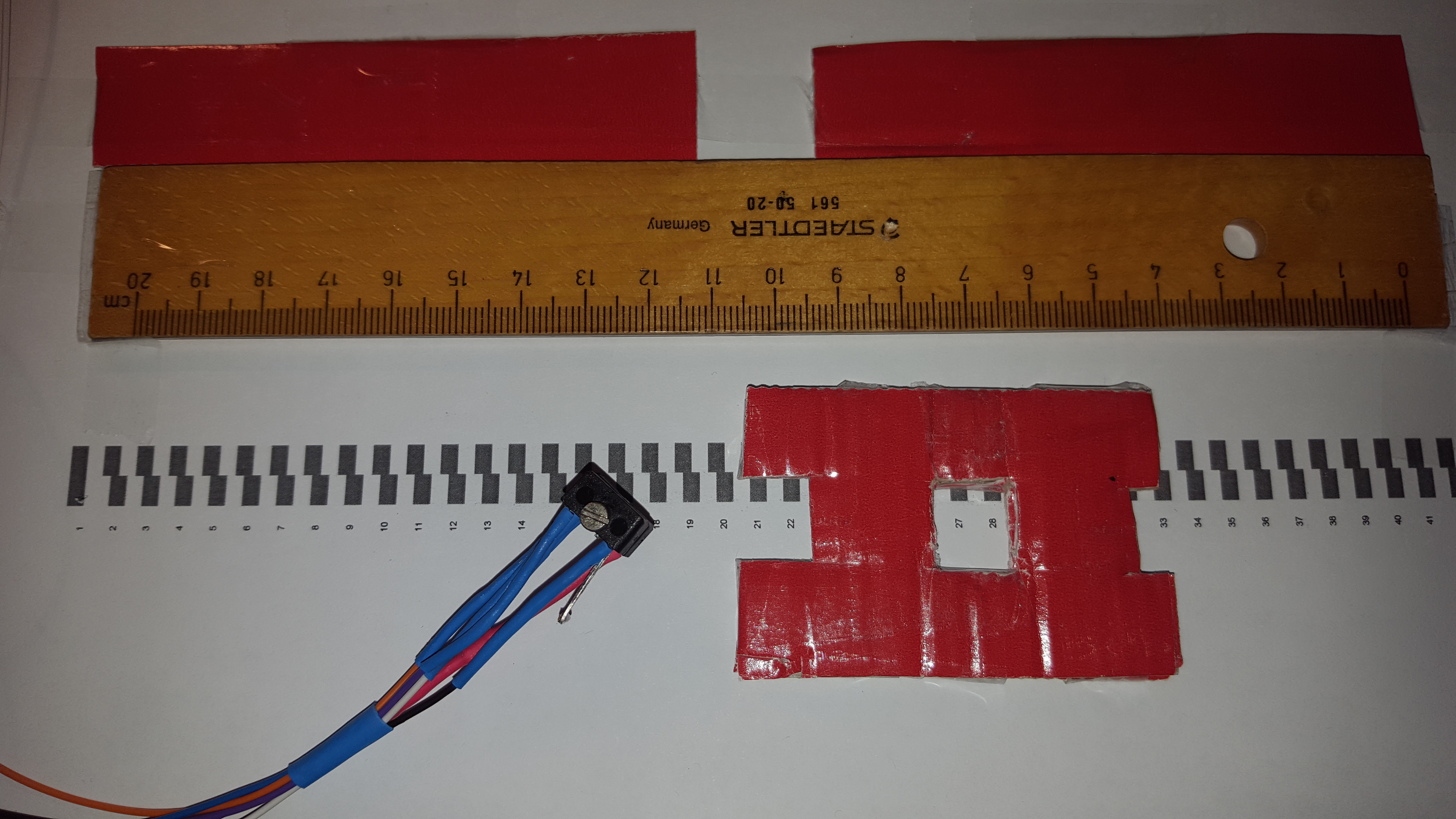

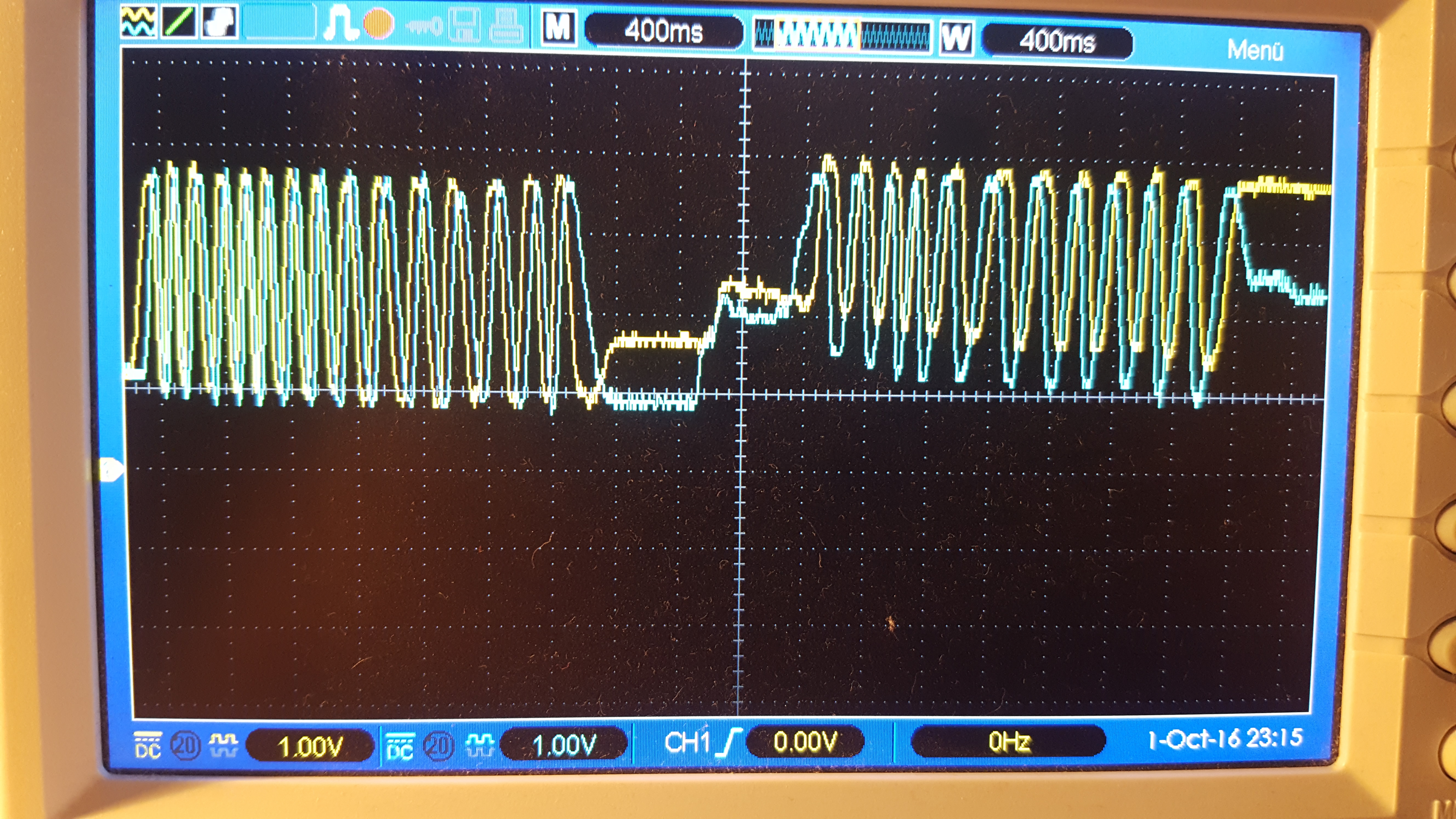

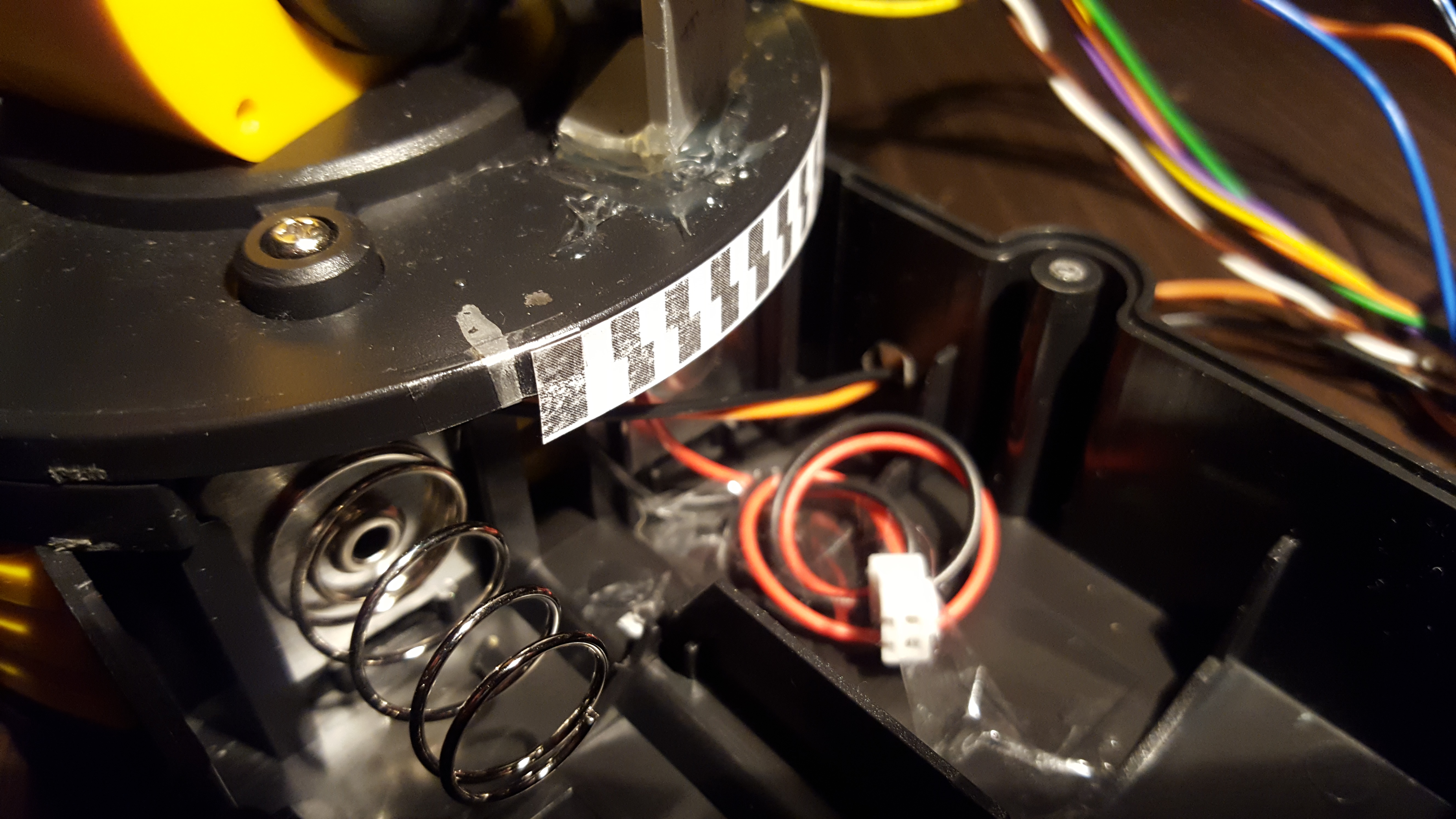

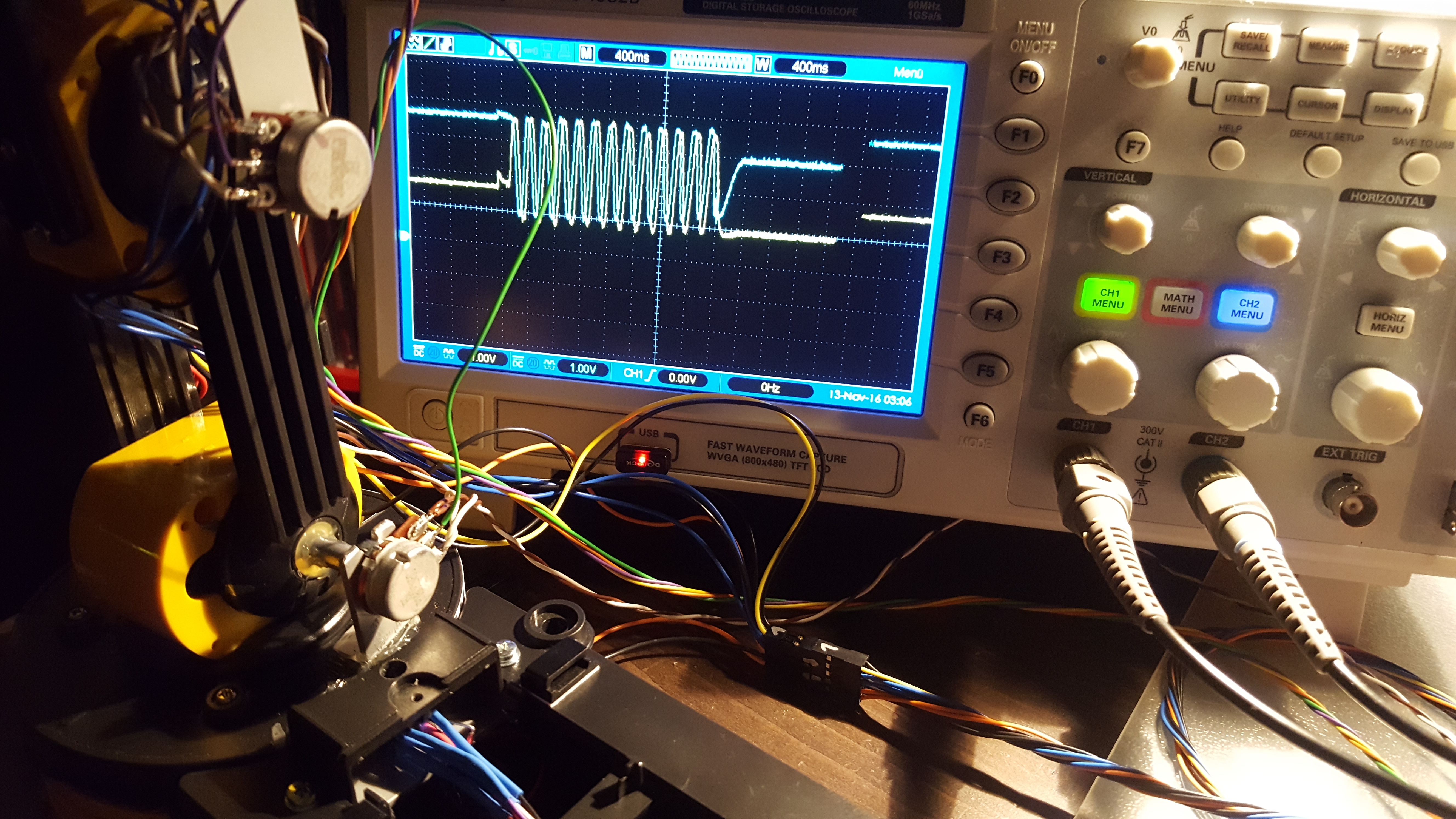

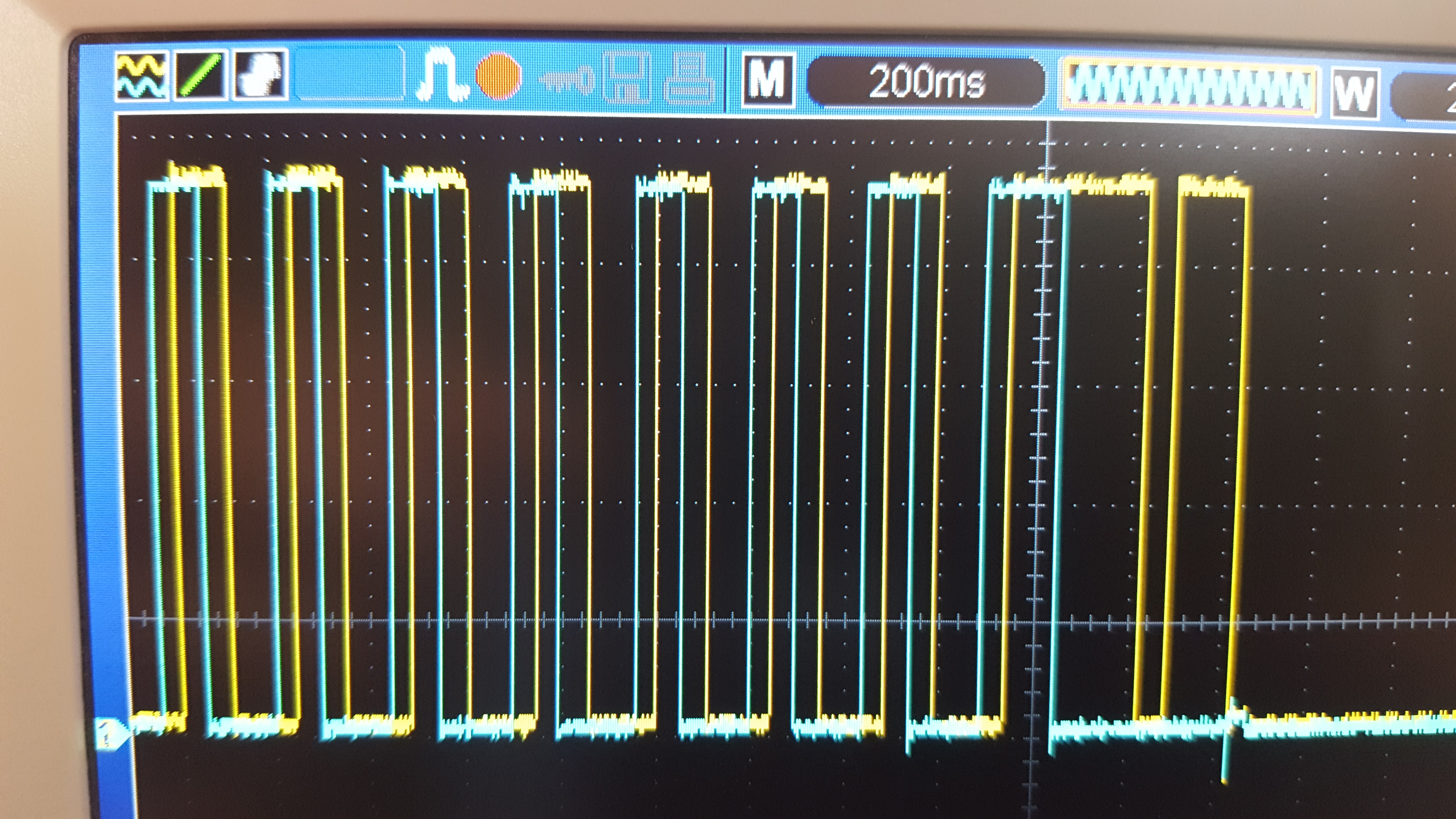

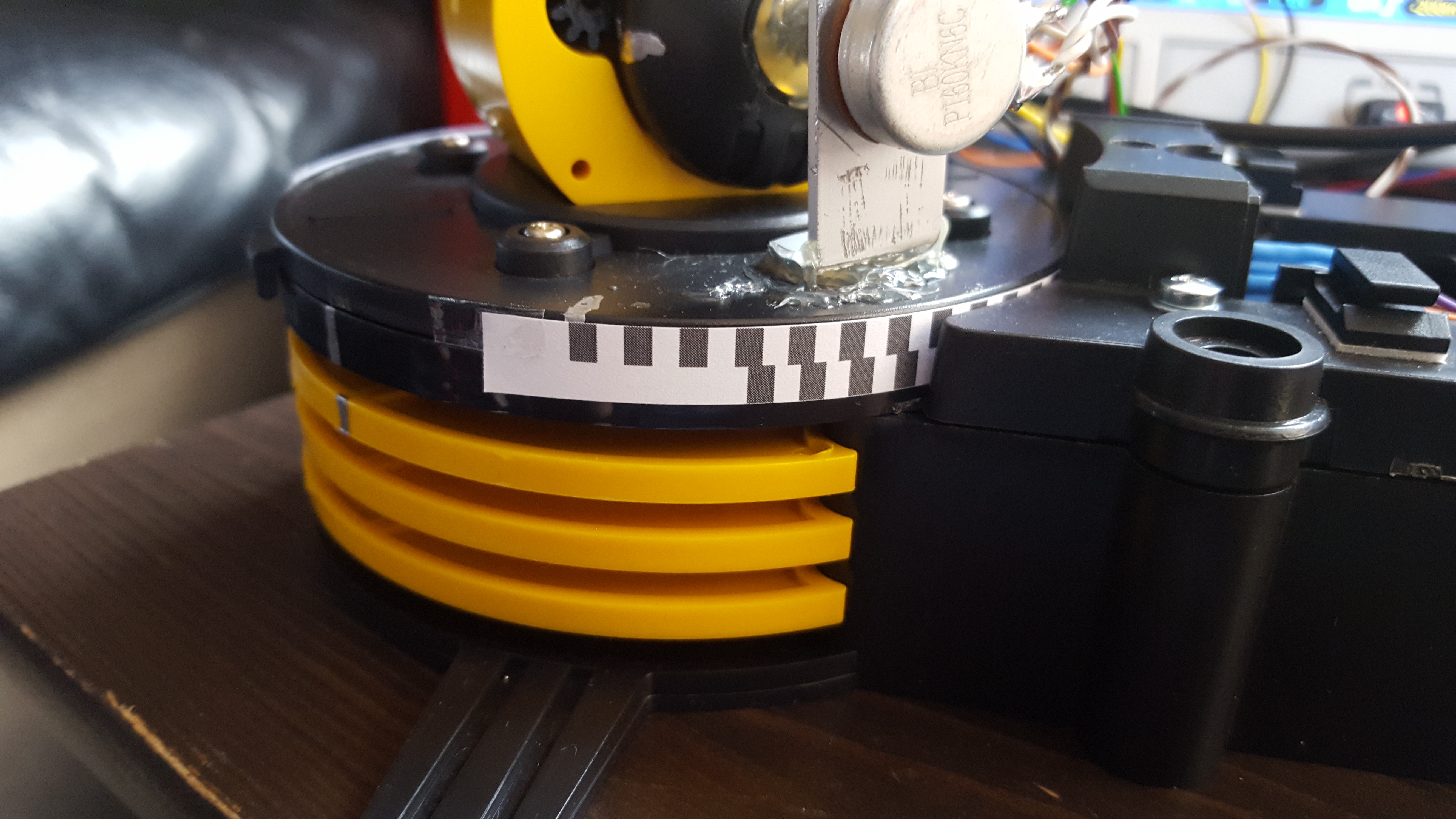

The rotation angle of the base plate is detected using an optical trigger belt and an ITR 9904 opto interrupter. The analoge signal of the ITR 9904 is converted into a TTL signal using a Schmitt-Trigger.

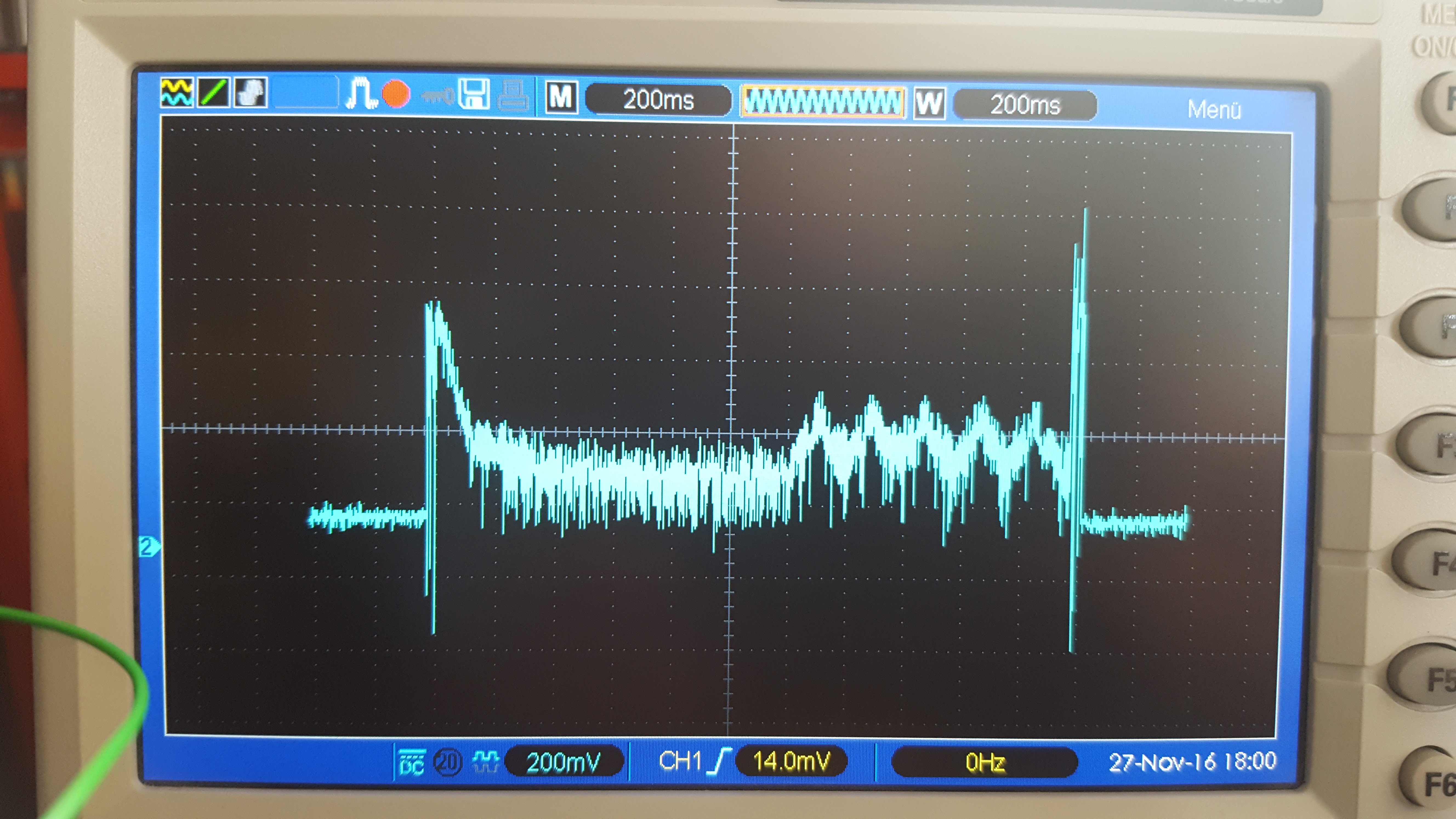

Object grabbing is force-controlled using a shunt resistor and current measurement. This allows for a proper grabbing of objects with different dimensions.

Points selected in the real world height-radis-angle coordinates are converted into indivdual joint angles. Positions can be stored and replayed using the python user interface.